The pharmaceutical industry is evolving faster than ever before. With global regulatory demands, advanced technologies, and increasing competition, the need for pharmaceutical engineering services has become essential for every forward-thinking drug manufacturer.

At JD Pharma Consultant, a leading Pharma Consultancy Company in India, we believe engineering excellence is the foundation of innovation in pharma. From conceptual design to plant commissioning, pharmaceutical engineering defines how safe, efficient, and scalable modern drug manufacturing can be.

The Changing Face of Drug Manufacturing

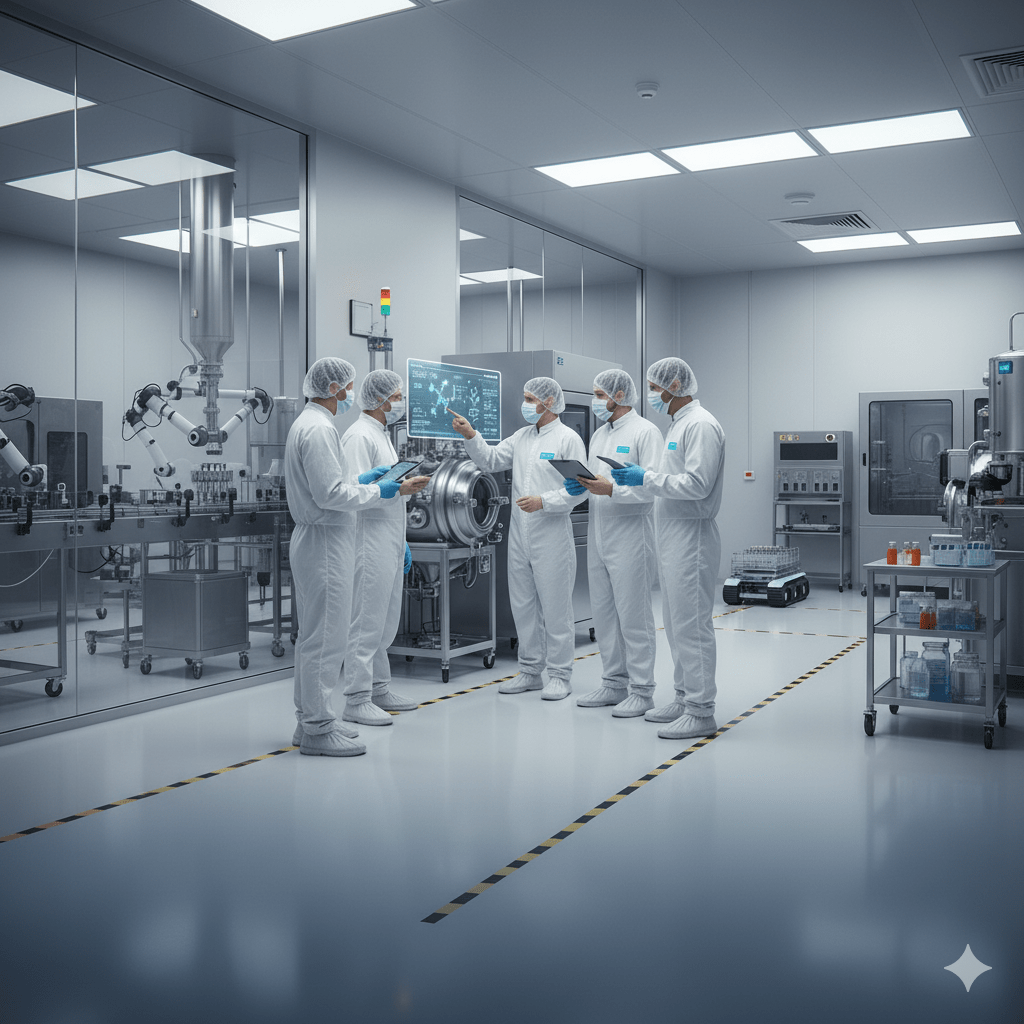

Gone are the days when pharmaceutical plants operated with rigid, manual systems. Today, facilities must be intelligent, digital, and compliant with global GMP standards.

Pharmaceutical engineering services combine design, technology, and compliance to help companies produce drugs more efficiently and safely.

Modern pharmaceutical manufacturing relies on:

- Process automation for accuracy and traceability

- Modular facility design for faster scale-up

- Sustainable utilities like energy-efficient HVAC systems

- Digital monitoring systems ensuring continuous compliance

These advancements make it possible for manufacturers to meet the ever-growing demand for high-quality medicines while maintaining profitability.

What Are Pharmaceutical Engineering Services?

Pharmaceutical engineering services refer to the specialized planning, design, and management of manufacturing facilities used to produce pharmaceutical products.

They cover every technical and compliance aspect of drug manufacturing, including:

- Facility layout and architectural design

- HVAC, cleanroom, and utility engineering

- Equipment selection and automation integration

- Validation and qualification (IQ/OQ/PQ)

- Process optimization and energy management

Essentially, these services bridge the gap between scientific innovation and commercial production ensuring medicines are produced under strict regulatory and quality standards.

Role of Pharmaceutical Engineering in Modern Manufacturing

Pharmaceutical engineers are the architects of modern medicine production. Their goal is to create facilities that deliver:

Efficiency: Smart layouts reduce movement, time, and waste.

Compliance: Every process meets WHO, US FDA, and EU GMP standards.

Flexibility: Plants are built to handle multiple formulations.

Sustainability: Energy and waste reduction are integrated from the design stage.

At JD Pharma Consultant, our expert engineers design plants that not only meet current requirements but also anticipate future regulations and technologies.

Core Areas of Pharmaceutical Engineering Services

To stay ahead, engineering services cover several critical domains:

1. Facility Layout & Plant Design

A well-designed pharmaceutical manufacturing plant layout is the backbone of efficiency. It defines product flow, clean zones, material movement, and contamination control.

2. Process & Utility Engineering

Designing clean utilities such as Water for Injection (WFI), HVAC, and compressed air is key to maintaining GMP conditions.

3. Automation & Control

Modern plants adopt PLC, SCADA, and IoT-based automation systems for real-time data monitoring and batch traceability.

4. Validation & Qualification

Pharmaceutical engineering services include complete validation from design qualification (DQ) to performance qualification (PQ) ensuring your plant is audit-ready.

5. Regulatory Compliance

Engineering aligns with standards such as US FDA, WHO-GMP, MHRA, and EU GMP, making your plant globally competitive.

Why India Leads in Pharmaceutical Engineering Services

India has emerged as a global hub for pharmaceutical manufacturing, exporting medicines to over 200 countries.

Partnering with a Pharma Consultancy Company in India provides:

- Cost-effective project delivery

- Local & international regulatory know-how

- Access to world-class engineering expertise

- Proven project management experience

Indian consultants, like JD Pharma Consultant, combine deep technical skills with a clear understanding of global compliance, making them the preferred choice for turnkey pharma projects worldwide.

How Pharmaceutical Engineering Services Shape the Future

Here’s how these services are transforming modern drug manufacturing:

1. Digital Transformation

With the rise of Pharma 4.0, digital twins, AI, and predictive analytics are redefining plant operations. Engineering services now integrate IoT devices, real-time data systems, and digital validation platforms for smarter production.

2. Sustainable Manufacturing

Green engineering practices like renewable energy systems and waste reduction are now essential. Sustainable design ensures both regulatory compliance and long-term profitability.

3. Personalized Medicine

As the world moves toward precision medicine, pharmaceutical engineering helps create adaptable facilities capable of producing small, specialized batches efficiently.

4. Faster Time-to-Market

Using advanced simulation, modular construction, and agile project management, modern engineering solutions reduce the timeline from concept to commercial production.

5. Global Compliance and Quality

Engineering services embed compliance into every design layer, ensuring plants are audit-ready for US FDA, WHO-GMP, and EU GMP inspections.

The Role of Project Management in Pharmaceutical Industry

Behind every successful engineering project lies strong project management.

In the pharmaceutical industry, project management ensures:

- Clear timelines and milestones

- Risk assessment and mitigation

- Budget control and resource allocation

- Coordination among multidisciplinary teams

JD Pharma Consultant integrates project management in pharmaceutical industry practices with engineering excellence, ensuring on-time and within-budget project delivery.

The Benefits of Partnering with Pharmaceutical Manufacturing Consultants

Collaborating with expert pharmaceutical manufacturing consultants ensures you receive:

- Turnkey solutions – from concept to commissioning

- GMP-compliant design

- Reduced operational costs through process optimization

- Quality-driven execution across all project stages

- Continuous support for future expansions and audits

Our holistic approach transforms your vision into a fully compliant, world-class facility.

Future Trends in Pharmaceutical Engineering

The next decade will redefine drug manufacturing. Expect to see:

- AI-driven process monitoring and predictive maintenance

- Continuous manufacturing replacing batch production

- Modular cleanroom systems for flexibility

- Fully digital quality documentation

- Integration of 3D printing and robotics in production

These advancements will make pharmaceutical manufacturing more adaptive, efficient, and sustainable driven entirely by smart engineering solutions.

FAQs About Pharmaceutical engineering services

1. What are Pharmaceutical Engineering Services?

Pharmaceutical engineering services involve designing, validating, and optimizing facilities that manufacture medicines. They include plant layout, utility design, automation, validation, and compliance support to ensure consistent quality and efficiency.

2. What regulatory standards do you comply with?

At JD Pharma Consultant, we follow global standards such as WHO-GMP, US FDA, EU GMP, and ISO 9001. Every facility design and validation aligns with international regulatory expectations.

3. Do you provide support for facility upgrades or expansions?

Yes, we specialize in plant modernization, capacity expansion, and technology upgradation. Our team ensures minimal disruption and maximum compliance during every expansion project.

Why Choose JD Pharma Consultant

As one of the Top Pharma Consultancy Companies in India, JD Pharma Consultant provides end-to-end pharmaceutical engineering services—from feasibility studies to turnkey plant setup.

Our expertise includes:

- Conceptual & Detailed Engineering

- HVAC & Utility Design

- Equipment Procurement & Installation

- CQV (Commissioning, Qualification & Validation)

- Training & Regulatory Audit Support

With decades of experience, we deliver reliable, compliant, and future-ready facilities for pharmaceutical manufacturers across the globe.

Conclusion

Pharmaceutical engineering is the backbone of innovation and efficiency in modern drug manufacturing. As the industry faces tighter regulations, complex therapies, and digital transformation, pharmaceutical engineering services will continue to define how drugs are designed, produced, and delivered.

Whether it’s a new facility or an upgrade to an existing one, expert engineering ensures compliance, efficiency, and sustainability all while meeting market demands faster.