Top Strategies to Enhance Productivity in Pharma Plant Operations

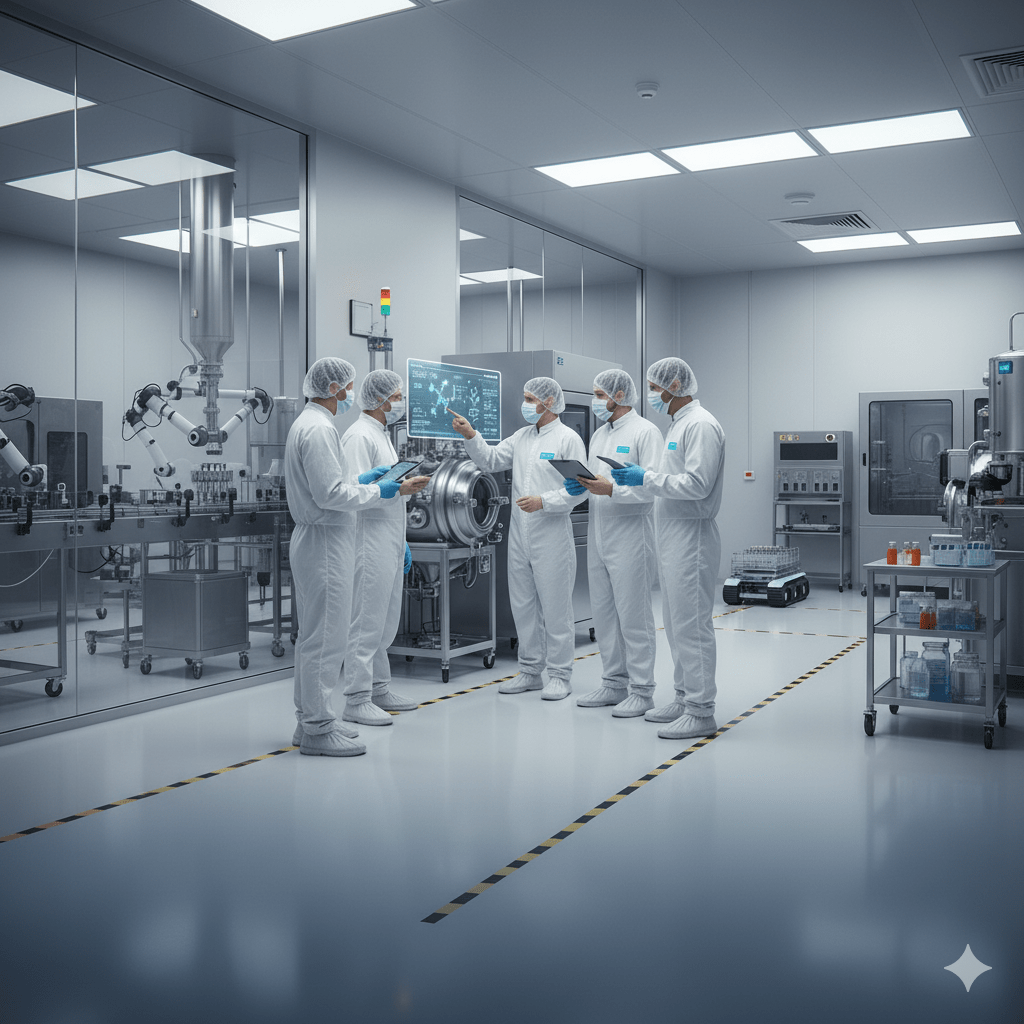

In today’s fast-paced pharmaceutical industry, enhancing productivity isn’t optional it’s vital for growth, compliance, and competitiveness. Whether you’re designing a new facility or optimising an existing one, partnering with expert pharmaceutical plant design consultants and focusing on smart operations can significantly boost efficiency and output. At JD Pharma Consultant, one of the leading Pharma Consultancy Companies in India, we help pharmaceutical manufacturers enhance their operational efficiency through strategic planning, plant design optimisation, and implementation of global best practices. Optimize the Layout of Pharmaceutical Manufacturing Plant The layout of pharmaceutical manufacturing plant plays a critical role in achieving operational efficiency. A well-structured pharmaceutical manufacturing plant layout design ensures smooth material flow, prevents cross-contamination, and reduces unnecessary movement of personnel and materials. Best practices for effective plant layout design: A professional pharmaceutical plant design consultant can assess your process flow and create a layout that balances efficiency, compliance, and scalability ensuring every square foot contributes to productivity. Embrace Digital Transformation and Automation Digitalisation is revolutionising pharma manufacturing. By automating manual processes and integrating smart systems, plants can significantly increase throughput and accuracy. Automation strategies to improve productivity: Automation not only improves operational speed but also enhances compliance by ensuring data integrity a critical factor for WHO-GMP and USFDA approvals. Implement Total Productive Maintenance (TPM) Practices Equipment downtime is a hidden productivity killer. Adopting Total Productive Maintenance (TPM) ensures that every machine operates at its best performance level. Key TPM principles: A TPM-driven culture encourages ownership, reduces breakdown frequency, and sustains long-term operational reliability. Empower Your Workforce Through Training and Engagement No matter how advanced your facility is, productivity depends on your people. A motivated and skilled workforce ensures consistent performance and quality output. Ways to build a high-performance team: When employees understand their role in operational excellence, engagement and efficiency rise naturally. Monitor Key Performance Indicators (KPIs) Regularly What gets measured gets improved. KPIs in the pharmaceutical industry provide actionable insights into productivity and quality. Essential KPIs for pharma plants: Tracking these metrics through real-time dashboards helps identify bottlenecks and improve decision-making at all operational levels. Prioritize Quality and Compliance for Long-Term Efficiency Productivity and compliance go hand in hand. Ignoring quality leads to reworks, delays, and regulatory issues all of which hurt productivity. Quality-focused productivity improvements: Partnering with pharmaceutical plant design consultants ensures your facility’s design supports both GMP and productivity objectives. Streamline Changeovers for Multi-Product Efficiency Modern plants often handle multiple products and frequent changeovers. Reducing downtime during changeovers can significantly improve equipment utilisation. Changeover optimization tips: Efficient changeovers mean more batches, less idle time, and higher ROI from your facility investments. Use Data Analytics to Drive Smart Decisions Data is the new productivity engine. Advanced analytics allow you to detect inefficiencies and continuously refine processes. Smart data applications: By combining analytics with expert insights from a Pharma Consultancy Company in India, you can make informed, data-driven improvements that compound over time. Adopt Continuous Improvement and Lean Manufacturing Lean manufacturing and continuous improvement eliminate non-value-adding activities, ensuring every process step contributes to the final goal. Core lean practices for pharma operations: These practices foster a culture of efficiency and innovation the hallmark of world-class pharma plants. Collaborate with Expert Pharmaceutical Plant Design Consultants To achieve long-term productivity, you need more than just internal efforts you need external expertise. Professional pharmaceutical plant design consultants combine technical, regulatory, and operational insights to transform your facility’s performance. Why work with JD Pharma Consultant: By choosing JD Pharma Consultant, you ensure your plant is designed for maximum efficiency, safety, and compliance from layout to live production. FAQs About pharmaceutical plant design consultant 1. What measures were implemented to improve productivity in the factory? To improve productivity, factories optimize plant layout, automate production processes, adopt TPM practices, train staff, and track KPIs such as OEE and yield. Implementing lean manufacturing and predictive maintenance also minimizes downtime and waste. 2. What is KPI in pharmaceutical industry? A KPI (Key Performance Indicator) measures performance in critical areas such as equipment efficiency, cycle time, yield, and quality compliance. These metrics help management track progress, identify inefficiencies, and drive continuous improvement in pharma operations. 3. What is TPM in pharma industry? TPM (Total Productive Maintenance) is a proactive maintenance system that involves all employees in maintaining equipment efficiency. It focuses on reducing breakdowns, improving uptime, and sustaining high performance through preventive maintenance and operator involvement. Conclusion Boosting productivity in pharmaceutical plant operations demands a strategic blend of efficient design, advanced technology, skilled manpower, and continuous improvement. By working with seasoned pharmaceutical plant design consultants like JD Pharma Consultant, you can build or optimize a facility that meets global compliance standards while delivering maximum efficiency.