Struggling to design an HVAC system for your pharmaceutical or biotech facility that meets strict regulatory standards? Ensuring compliance while maintaining efficiency can be daunting. This blog post dives into turnkey pharmaceutical projects and HVAC clean room validation, offering practical solutions to streamline your pharma facility design. You’ll discover how pharmaceutical turnkey solutions simplify the process, ensure compliance, and boost performance, saving you time and resources.

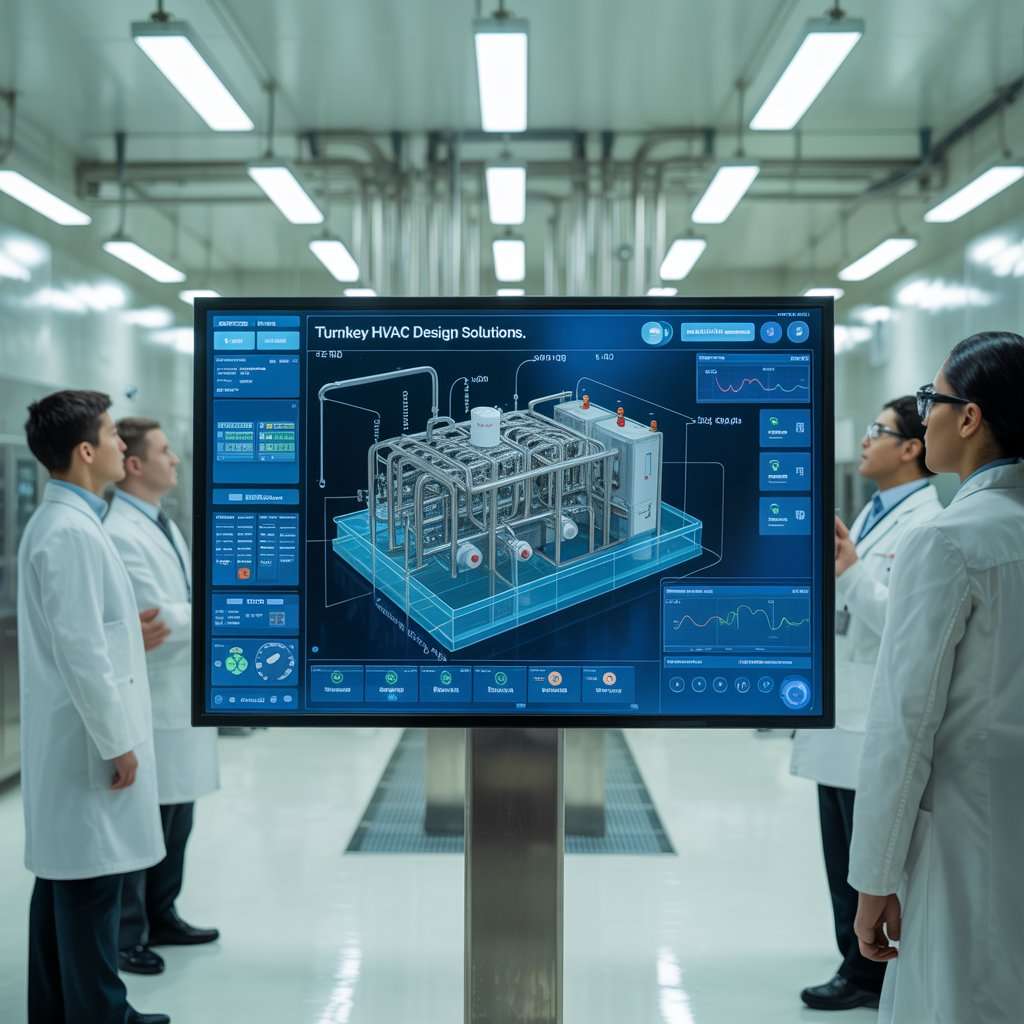

What Are Turnkey HVAC Design Solutions?

Turnkey pharmaceutical projects provide comprehensive solutions for designing, installing, and validating HVAC systems in pharma and biotech plants. These solutions cover everything from planning to execution, ensuring your facility aligns with industry standards like GMP (Good Manufacturing Practices).

Why Choose Turnkey Solutions?

- Saves Time: A single provider manages the entire project, reducing coordination challenges.

- Ensures Compliance: Experts in pharma compliance consulting align your HVAC system with FDA and EU regulations.

- Cost-Effective: Streamlined processes minimize unexpected expenses.

- Customizable: Tailored to your specific pharma factory layout and production needs.

Partner with a trusted pharmaceutical consulting firm to ensure your HVAC system meets regulatory requirements from the start.

Key Components of HVAC Systems for Pharma Facilities

HVAC systems in pharmaceutical plants must maintain precise temperature, humidity, and air quality to ensure product safety. HVAC validation in pharma is essential to meet regulatory standards.

Essential Features

- Clean Room Compatibility: Uses HEPA filters and controlled airflow for sterile environments.

- Temperature and Humidity Control: Prevents contamination and ensures product stability.

- Energy Efficiency: Lowers operational costs without compromising performance.

- Monitoring Systems: Provides real-time data for compliance and troubleshooting.

Schedule regular HVAC clean room validation to ensure consistent compliance with ISO 14644 standards for clean rooms.

Steps to Implement Turnkey HVAC Solutions

Implementing pharmaceutical turnkey solutions follows a structured process to ensure seamless integration into your facility.

Step-by-Step Guide

- Needs Assessment: Work with experts to evaluate your pharma facility design requirements.

- Custom Design: Develop an HVAC system tailored to your pharma factory layout.

- Installation: Use experienced technicians for efficient, minimal-downtime installation.

- Validation and Testing: Conduct HVAC validation in pharma to confirm regulatory compliance.

- Ongoing Maintenance: Plan regular inspections to maintain system efficiency and compliance.

Link to a detailed guide on pharma facility design for tips on optimizing your layout for HVAC integration.

Benefits of Partnering with a Trusted Consulting Firm

A trusted pharmaceutical consulting firm brings expertise and reliability to your turnkey pharmaceutical projects.

Key Advantages

- Expert Guidance: Access specialists in pharma compliance consulting who understand regulatory requirements.

- Streamlined Project Management: Single-point coordination for design, installation, and validation.

- Risk Mitigation: Proactive solutions to avoid costly compliance issues.

- Scalability: Systems designed to grow with your production needs.

Learn more about regulatory standards at the FDA’s GMP guidelines.

FAQ: Common Questions About Turnkey HVAC Solutions

What is HVAC clean room validation?

HVAC clean room validation ensures your HVAC system maintains required air quality, temperature, and humidity for sterile environments, per ISO and GMP standards.

How do turnkey solutions save costs?

By managing the entire project, pharmaceutical turnkey solutions reduce inefficiencies and prevent costly errors.

Why is pharma compliance consulting important?

Consulting ensures your facility meets strict regulations, avoiding penalties and ensuring product safety.

Conclusion

Turnkey HVAC design solutions simplify the process of creating compliant, efficient systems for pharma and biotech plants. Partnering with a trusted pharmaceutical consulting firm streamlines pharma facility design and ensures HVAC clean room validation. Ready to optimize your facility? Contact us to explore pharmaceutical turnkey projects tailored to your needs. Share your thoughts or questions in the comments below!